Written by Occupli Health & Safety Consultant Aisling Hegarty

A recently published article in the Health & Safety Review reported on a recent webinar, hosted jointly by the Workplace Health Leadership Group in Northern Ireland (WHLGNI) and the British Occupational Hygiene Society (BOHS), during which welding was highlighted as one of the top ten causes of work related cancer.

Welding has long been associated with causing serious acute and chronic health effects. This is due to exposure to potentially hazardous chemical agents in the welding fumes. According to the article, there has been a growth in recruitment for welders in Ireland, particularly in the year 2020. This greatly suggests the awareness surrounding the occupational health risks of welding fumes should be made priority.

What are the health risks associated with welding fumes?

There are two categories of ill-health effects from exposure to welding fume – acute and chronic health effects.

Acute (short term) health effects include:

- Irritation to the Upper Respiratory Tract

- High exposure to ozone can cause pulmonary oedema (fluid on the lungs);

- Headaches, dizziness nausea;

- Metal fume fever – causes flu-like symptoms and is associated with exposure to specific metals i.e. zinc.

Chronic (long-term) health effects include;

- Occupational Asthma – symptoms include episodes of severe shortness of breath, coughing, wheezing and chest tightness.

- Lung Cancer – associated with exposure to specific metals i.e. nickel and chromium.

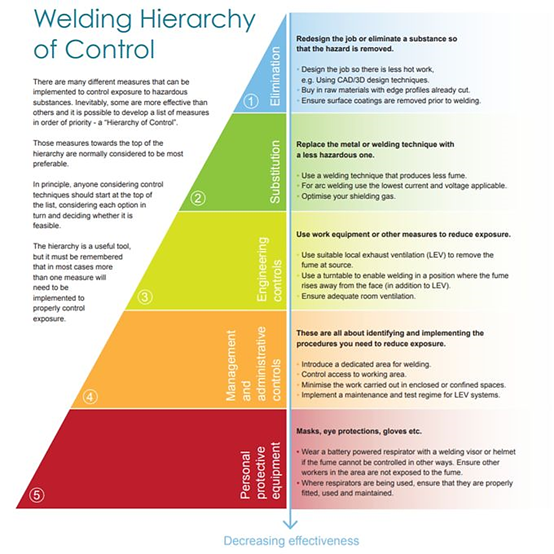

It is clear exposure to welding fume can lead to very serious and debilitating health conditions. As such, control measures should be implemented to eliminate or reduce the risks from welding fumes to workers. The Health and Safety Authority (HSA) website provides guidance on what controls are necessary for reducing exposure to welding fumes. The guidance recommends using the ‘hierarchy of control’ system in which the most effective control measures should be consider priority, such as Elimination, Substitution and Engineering controls. Whereas the less effective controls such as Administration and Personal Protective Equipment will be given less priority. However, a combination of different control measures such as engineering controls and Personal Protective Equipment (PPE) may be required to reduce exposure. Examples of engineering controls and use of PPE in welding tasks include robotic welding, use of on-gun extraction, local exhaust ventilation (LEV) and wearing of respiratory protective equipment (RPE).

In the UK, the Breathe Freely initiative developed by the British Occupational Hygiene Society (BOHS), aims to reduce occupational lung disease, particularly in the manufacturing and construction sector. The initiative has created a free online tool to help employers select the correct controls for welding tasks. The BOHS have recently shared a very useful diagram on the different measures to control exposure to welding fumes in the workplace using the ‘hierarchy of control’ system:

It is important employers communicate with welders on the health hazards of welding fumes through provision of information, instruction, and training. As the research on welding fume exposure continues to develop, employers must remain informed to ensure the health and safety of workers. Employers should undertake comprehensive risk assessments of any welding activities to take account of the specific circumstances of their operations and activities.

If you require further information or assistance please contact us via email at info@occupli.com, by phone at 021 497 8100 or start an instant chat with us via the chat box in the bottom right-hand corner of your screen.

Similar Topics:

- Occupli Chemical Safety Consultancy. We specialise in compliance with the Safety, Health and Welfare at Work (Chemical Agents) Regulations, 2001. Read More

- Our machinery safety specialists provide practical advice, training and machinery solutions to support your particular needs. Our team work to legislative requirements and benchmark against industry best practice. Read More

- Abrasive Wheels Training Courses and Abrasive Wheels Instructor Training Course Read More