Gary Horgan (CMSE Consultancy Manager at the Chris Mee Group) and his team are outlining the path for companies to ensure they are compliant with Part 8 “Explosive Atmospheres at Places of Work” of the Health, Safety & Welfare at Work (General Applications) Regulation 2007 in a series of focussed blogs.

- Blog 1, Explosion Accidents 2020

- Blog 2, Preparing for an Explosion Protection Document

- Blog 3, Summary of Legal Requirements

- Blog 4, What Are Explosions?

- Blog 5, Characteristics of Flammable Liquids, Gases and Vapours

- Blog 6, Hazardous Area Classification – Dust

Hazardous area classification is a technique used to assess an area to determine the likelihood that a flammable atmosphere will occur and the duration that it’s likely to occur for.

One of the main reasons for hazardous area classification is to help employers choose safe equipment and processes for specific locations. Standard electrical and electronic equipment produce sparks and heat both during normal operation and when they malfunction. Some clothing fabrics can generate static on their surface which can then discharge, similarly, a spark could be generated as a result of impact of hand tools on a surface. There are many other potential ignition sources. If sparks are introduced in locations where dust is present, it could lead to fire or explosion. Specially designed equipment that doesn’t produce heat or sparks is available for use in these areas.

For this reason, locations where an explosive atmosphere may occur must be assessed and classified. They can be classified into hazardous and non-hazardous areas. Hazardous areas are then sub classified into zones. The hazardous area classification zoning in turn is used when selecting equipment.

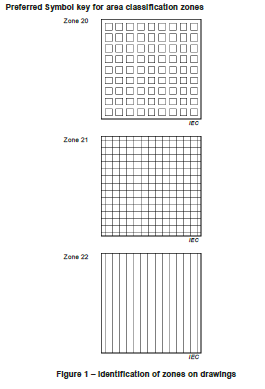

Two different zoning classifications are used depending on the properties of the flammable substances. Zone 0, 1 and 2 are used for gases, vapour and mists and Zone 20, 21 and 22 for dust.

Each location where a hazardous zone exits is individually assessed and assigned a zone based primarily on the frequency of an explosive atmosphere being present and the duration of an occurrence. Other criteria are also taken into consideration, including the physical properties of the material, the volume of material, and the likelihood of their presence in air during operations.

For dust, fine powder layers or a dust suspended in air as a dust cloud present the greatest risk. Good housekeeping and reducing the likelihood of dust clouds developing is good practice. Organic dusts that may seem harmless in general, can in fact be combustible e.g. sugar, flour and grain. Properties of specific dusts can increase or decrease the risk such as the lower explosive limit, minimum ignition temperature, or the burning behaviour of the dust. This information may be available on the Safety Data Sheet, unfortunately it’s common to see these sections left blank.

When considering the frequency of explosive atmospheres, the following is used:

Zone 20: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously or for long periods or frequently (>1000 hours per year).

Zone 21: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally (10 – 1000 hours per year).

Zone 22: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only (<10 hours per year).

Figure 1 Zoning symbols for hazardous area classification drawing from EN 60079-10.

For an explosion grade of release, the terms used are:

Continuous: Expected to occur for long periods (Zone 20).

Primary: Periodically during normal operation (Zone 21).

Secondary: Not expected in normal operation but of it does, it’s for short periods, infrequently (Zone 22).

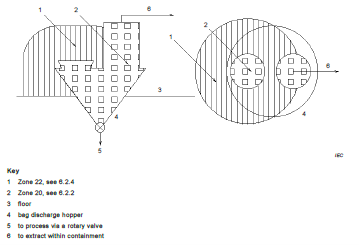

The extent of the zone will also be assessed and should incorporate vertical and horizontal distance from the point of release. The size of the zone will depend again on potential risks associated with the dust and the grade of release. Typically, if for example you have a Zone 21 for 1.5m from an opening, it’s likely you might have a Zone 22 outside that and maybe a non-hazardous outside that as you get further away. It’s important to assess each individual location to determine the zone and the extent of it. The operator of the site must prepare hazardous area classification drawings for their operations indicating the potential zones.

Example of Dust Zoning from EN 60079-10 Electrical Apparatus for Explosive Dust Atmospheres.

Refer to EN 60079-10 Electrical Apparatus for Explosive Dust Atmospheres – Part 10: Classification of Hazardous Areas for more guidelines of the dust explosion hazard.

Areas classified into zones should be marked with yellow and black ‘EX’ signage at entry points to alert personnel of the risks and make it known that there are additional rules for equipment and clothing.

Further information is available on our Process Safety Blogs linked above.

Next week we will discuss the Hazardous Area Classification – Gases & Vapours

CMSE Consultancy provide a professional Health, Process, Explosion & Fire Safety Services.

If you require further information or assistance please contact us via email at info@cmse.ie, by phone at 021 497 8100 or start an instant chat with us via the chat box in the bottom right-hand corner of your screen.