Gary Horgan (CMSE Consultancy Manager at the Chris Mee Group) and his team are outlining the path for companies to ensure they are compliant with Part 8 “Explosive Atmospheres at Places of Work” of the Safety, Health & Welfare at Work (General Application) Regulations 2007 in a series of focussed blogs.

This is blog number 8 in the series.

- Blog 1, Explosion Accidents 2020

- Blog 2, Preparing for an Explosion Protection Document

- Blog 3, Summary of Legal Requirements

- Blog 4, What Are Explosions?

- Blog 5, Characteristics of Flammable Liquids, Gases and Vapours

- Blog 6, Characteristics of Combustible Dusts and Powders

- Blog 7, Hazardous Area Classification – Dusts

- Blog 8, Hazardous Area Classification – Liquids, Gases and Vapours

Introduction

In this blog, we will be discussing the process for the Hazardous Area Classification for the handling of flammable liquids, gases, and vapours.

As we discussed previously for dusts, Hazardous Area Classification is a process used to assess an area to determine the likelihood that a flammable atmosphere will occur and the duration that it’s likely to occur for.

Why is Hazardous Area Classification Important?

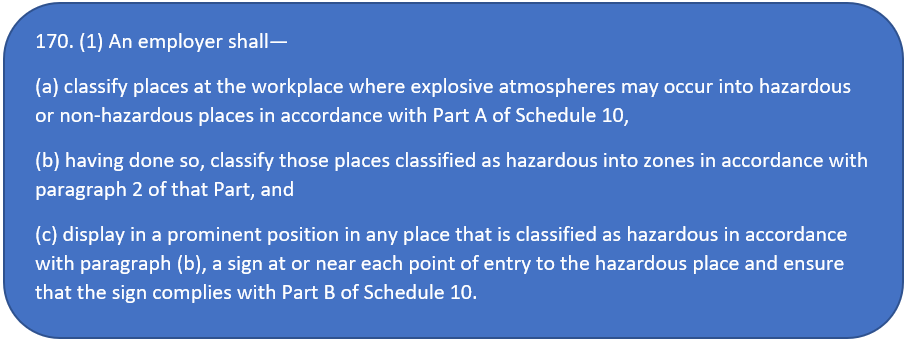

In all EU Member States, it is a requirement for all workplaces handling flammable materials to undertake this process as part of the ATEX Workplace Directive (ATEX 137). In Ireland, this mandatory legal requirement is transposed into Irish law by Regulation 170 of the General Application Regulations 2007:

One of the main reasons for hazardous area classification is to help employers choose safe equipment and processes for specific locations. Standard electrical and electronic equipment produce sparks and heat both during normal operation and when they malfunction. Some clothing fabrics can generate static on their surface which can then discharge, similarly, a spark could be generated as a result of impact of hand tools on a surface.

There are many other potential ignition sources. If sparks are introduced in locations where an explosive atmosphere could be present, it could lead to fire or explosion

Description of Zones

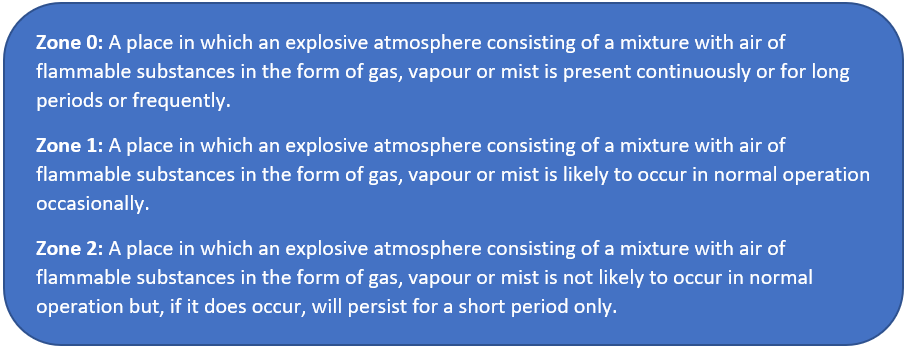

So, the regulations refer to specific “zones” for areas that are identified as being hazardous. These are:

General guidance on how to determine the location and extent of these zones is available in the engineering standard EN 60079-10-1:2015. There are also industry specific guides and standards available for specific types of processes and facilities, such as the Energy Institute’s “Model Code of Safe Practice Part 15” for the oil and gas industry.

It is important that this is carried out by someone who is competent to do so, as it often requires calculations to be carried out using the explosive characteristics of the material and the available ventilation.

Effect of Ventilation on Zones

Where potentially flammable atmospheres arise, ventilation in the area can have a large impact on the type and extent of the hazardous zone. Ventilation may be either natural or artificial. Natural ventilation is the movement of air by wind or temperature gradients. Artificial ventilation is caused by fans, extractors etc. With the use of artificial ventilation, it is possible to achieve;

- Reduction in the type and/or extent of zones;

- Shortening of the time of persistence of an explosive atmosphere;

- Prevention of the generation of an explosive atmosphere.

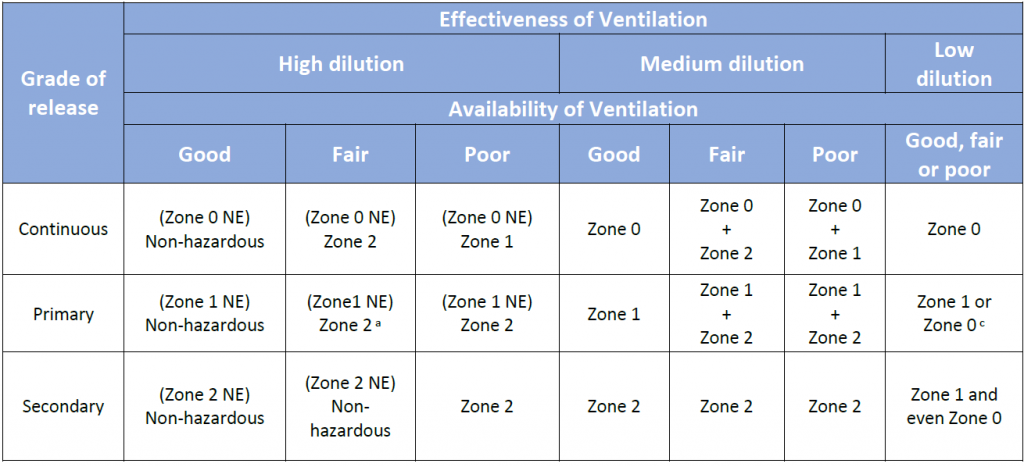

Engineering standard EN 60079-10-1:2015 includes the following table which summarises the potential effect of the available ventilation on the type of zone:

Example of Hazardous Area Classification

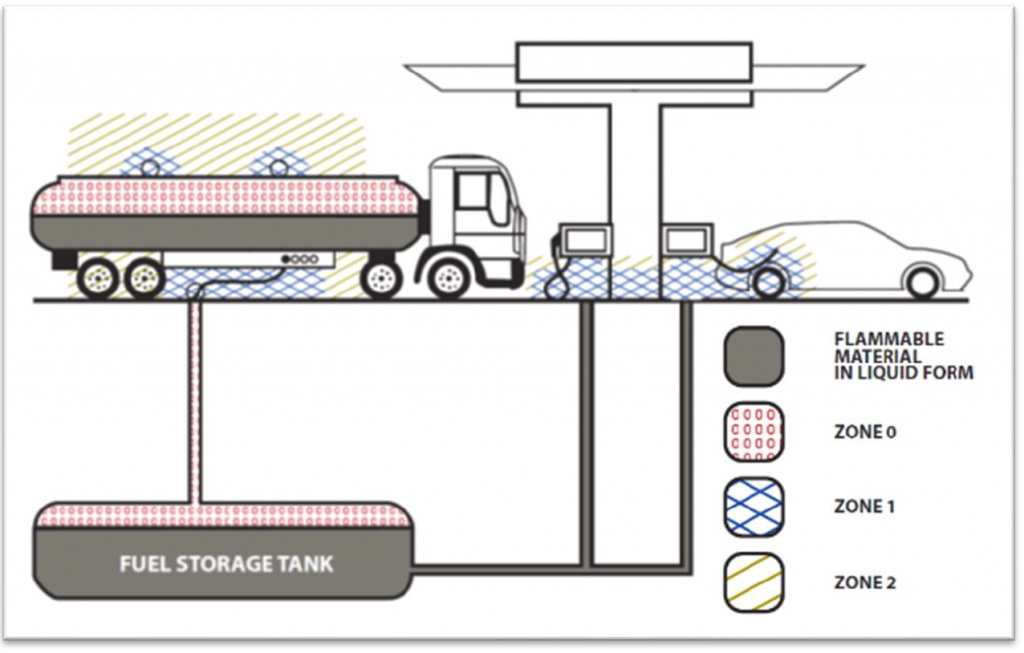

In our ATEX awareness training, we often use a petrol station as a useful example to illustrate how hazardous area classification may work in practice.

As can be seen in the graphic above (adapted from HSA website), a Zone 0 is often identified in the headspace of tanks containing flammable liquids which are being stored at or above their flashpoint. In this case Zone 0s are identified in the headspace of the road tanker storage tank and the below ground fuel storage tank, as an explosive atmosphere will be present continuously.

Zone 1s are identified around filling/dispensing points (with an approximately 1 – 1.5m radius), such as around the connectors on the road tanker and the petrol pump filling head, as it is likely that a potentially explosive atmosphere will be present in these areas during filling operations. A Zone 1 is also identified around the gas release vents in the top of the road tanker.

Zone 2s are identified for a larger extent around the Zone 1s, as in the event of a maloperation such as a spillage of petrol. The release point would be the same, but the volume of a potentially explosive atmosphere will be larger. The size of the Zone 2 will be, in part, based on the maximum credible volume of petrol that could be released in a spill.

CMSE Consultancy provide professional Occupational, Process, Explosion & Fire Safety Services.

If you require further information or assistance please contact us via email at info@cmse.ie, by phone at 021 497 8100 or start an instant chat with us via the chat box in the bottom right-hand corner of your screen.